Reducing noise, vibration and harshness has become a technology in itself. Vehicle manufacturers are striving to refine their vehicles with vibration isolators and countermeasures to reduce these characteristics.

- Noise is an unpleasant or disturbing sound that causes some sort of disturbance. An example would be the rattling of a worn bearing.

- Vibration is the discouraging and repetitive motion of an object. An unbalanced tire can cause the steering wheel to wobble at certain speeds.

- Harshness is very subjective. It can be defined as a sudden, jarring sensation. A similar sensation would be driving through a pothole.

The biggest contributor to these characteristics is the internal combustion engine. This can be attributed to rotating parts, combustion, and speed variation. These characteristics are further amplified in engines featuring stop/start technology, cylinder deactivation, and increased compression ratios.

Vehicle manufacturers use a variety of shapes, sizes, and types of mounts to isolate the engine. This is intended to counteract these characteristics. The type used depends on the characteristics of the vehicle's engine, the costs involved, and the perceived quality of the brand.

The three main types of mounts used are: rubber, hydraulic and electronically active.

Rubber supports

Rubber mount is a traditional type of mount and is the most commonly used. It comes in many shapes and sizes ranging from a simple real cotton form to a very complex rubber and metal formation. The stiffness is regulated within the properties of the elastomeric material used. The direction of movement is determined by the fixed links within the frame design.

Hydraulic supports

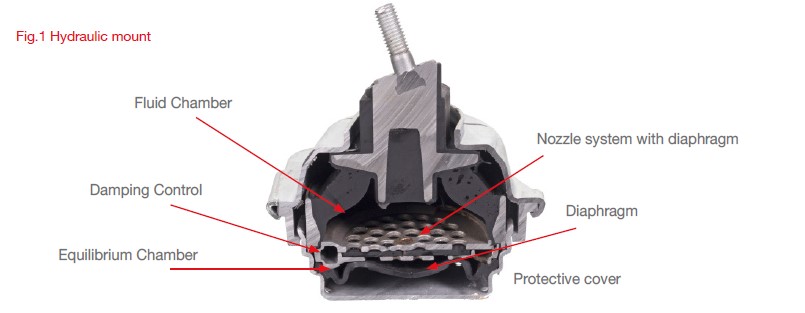

The hydraulic mount is more dynamic and combines the sound insulation functions of a conventional rubber engine mount, but with balanced damping performance. Hydraulic engine mounts can adapt their characteristics depending on the induced load. The viscous liquid in the hydraulic mount acts as a shock absorber to ensure optimal insulation.

Inside a hydraulic engine mount, the rubber main spring has an upper and lower chamber. The chambers are connected by a series of channels and separated by a rubber valve. The main spring is filled with a viscous liquid. During impacts, the rubber valve opens and closes the bypass channel, redirecting the flow of the viscous liquid between the two chambers. This changes the stiffness of the mount, creating optimal damping characteristics for any road condition. (Fig. 1)

With more control required, one option to provide better adjustment for the hydraulic motor mount was to utilize the properties of vacuum. The negative pressure produced keeps the mount smooth at idle and low RPM. It also keeps it firm in the higher RPM range.

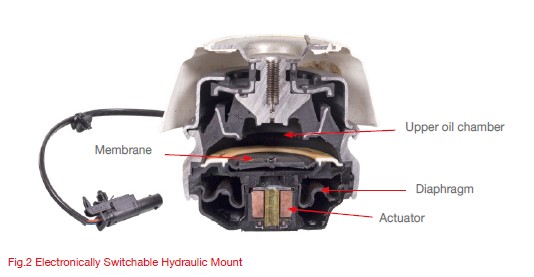

The evolution of hydraulic engine mount damping control comes from electronically switchable mounts that can be coupled with the vehicle's engine management system. (Fig. 2)

Electronically active mount

An electronically controlled engine mount meets the damping requirements, but with a little more control. The switch function causes the air suspension in the mount to be used in the neutral position. This provides a soft suspension when idling or at low revs. When the vehicle is driven, the mount switches to a hydraulic suspension and provides a firmer suspension between the engine and the vehicle body.

The latest development for engine mounts is the active and intelligent mount, designed to meet the most demanding functionality requirements. These are designed to save fuel and to be more in tune with the driving dynamics to offer maximum comfort.

An active, electronically switchable hydraulic mount is equipped with an actuator and sensors to provide feedback to the control unit. It can be actively controlled according to the required damping. This is driven by the excitation frequency of the actuator; the active mount damps hydraulically, passively or actively. The isolation characteristics are calculated by the vehicle control unit and converted by the actuator so that no vibrations are transmitted to the body.

Cause of wear and tear and failure

Over time, all engine mounts can fail or wear out. This can reduce their damping countermeasures and can cause unwanted vibration, noise, and harshness. This can be the result of the mount deteriorating over time and stress, or in the case of hydraulic mounts, fluid leaks.

Vacuum controlled mounts can have problems with air leaks and the vacuum system that controls them can wobble or stop working. This can cause more than vibration and can cause engine management problems.

Electronically controlled mounts can also suffer from the same fatigue issues. However, they have the added complexity of built-in electronics. Any electrical issues can be detected by the control unit and fault codes can be logged accordingly to aid in the diagnosis process.

When replacing any engine or transmission mount, make sure that all correct procedures are followed to avoid reducing the life of the replacement part.